Bonded cord strapping has gained significant traction in various industries due to its versatility and adaptability. Primarily made from bonded polyester cord, this strapping solution offers a cost-effective and lightweight alternative for applications where high break strength is not a critical requirement. In this article, we will delve into the properties, advantages, and applications of bonded cord strapping, as well as its potential impact on the global market.

Properties of Bonded Cord Strapping

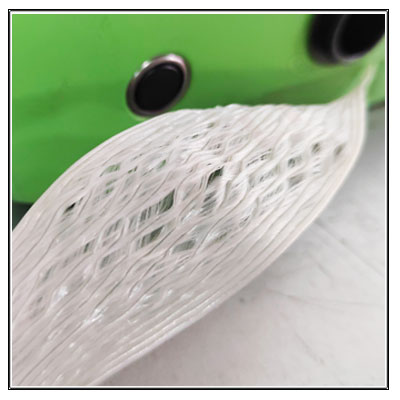

Bonded cord strapping is made from polyester yarns that are bonded together using a thermoplastic resin. This unique manufacturing process results in a lightweight yet strong strapping material that can withstand various environmental conditions. Some of the key properties of bonded cord strapping include:

1. Lightweight: The lightweight nature of bonded cord strapping makes it easy to handle and reduces transportation costs.

2. Strong and durable: Despite its lightweight design, bonded cord strapping offers sufficient strength for most low-strength applications.

3. Resistant to abrasion and moisture: The thermoplastic resin coating provides excellent resistance to abrasion and moisture, ensuring long-lasting performance.

4. Easy to use: Bonded cord strapping is user-friendly and can be applied using standard strapping tools.

5. Cost-effective: Compared to other strapping materials, bonded cord strapping offers a more affordable solution for low-strength applications.

Advantages of Bonded Cord Strapping

The unique properties of bonded cord strapping offer several advantages for users across various industries. Some of the key advantages include:

1. Versatility: Bonded cord strapping can be used in a wide range of applications, from packaging and捆扎 to捆扎 and reinforcement.

2. Eco-friendly: The polyester yarns used in bonded cord strapping are recyclable, making it an environmentally friendly option.

3. Easy storage and transportation: Due to its lightweight design, bonded cord strapping is easy to store and transport, reducing storage and transportation costs.

4. Durable and long-lasting: The thermoplastic resin coating provides excellent resistance to abrasion and moisture, ensuring a long service life.

Applications of Bonded Cord Strapping

Bonded cord strapping has numerous applications across various industries, including:

1. Packaging: Bonded cord strapping is widely used for packaging goods, such as boxes, pallets, and crates, providing a secure and reliable bundle solution.

2.Bundle: Bonded cord strapping is ideal for bundle applications, such as bundle pipes, cables, and hoses, offering a strong and durable bundle solution.

3. Reinforcement: Bonded cord strapping can be used to reinforce concrete, timber, and other structural elements, providing additional strength and support.

4. Agriculture: Bonded cord strapping is used in agriculture for bundle hay bales, silage, and other agricultural products, ensuring secure transportation and storage.

Conclusion

Bonded cord strapping has emerged as a versatile and cost-effective solution for low-strength applications across various industries. With its lightweight design, strong and durable properties, and eco-friendly credentials, bonded cord strapping is set to become an increasingly popular choice for bundle and reinforcement applications. As the global market continues to evolve, the demand for bonded cord strapping is expected to grow, presenting opportunities for manufacturers and users alike.

BSTSTRAP

No.30 building, Wuxing High-tech Venture Park

Huzhou City, Zhejiang Province,China

Whatsapp:+86 136 6574 4776

Monday to Saturday 9 am to 5 pm

hailey@bststrap.com

Send us your enquiry anytime!

Others News

Bonded Cord Strapping: The Reliable and Cost-Effective Solution for Securing Your Goods

Bonded Cord Strapping: The Reliable and Cost-Effective Solution for Securing Your Goods BSTMELT Revolutionizes Product Bundling with Bonded Cord Strapping

BSTMELT Revolutionizes Product Bundling with Bonded Cord Strapping The Rise of Bonded Strapping: A Revolution in the Packaging Industry

The Rise of Bonded Strapping: A Revolution in the Packaging Industry Bonded Cord Strapping: The Multifaceted Solution for Securing and Bundling Across Industries

Bonded Cord Strapping: The Multifaceted Solution for Securing and Bundling Across Industries