In a world where efficiency is paramount, industries are constantly seeking innovative solutions to streamline processes and optimize productivity. A recent study has shed light on the remarkable efficiency gains achieved through the adoption of advanced bonded strapping techniques in packaging and logistics operations. This groundbreaking research not only underscores the importance of continuous innovation in the field but also highlights the significant impact that modern strapping technologies can have on enhancing operational efficiency and reducing costs.

Traditionally, strapping—used to secure and bundle goods for transportation and storage—has relied on conventional methods such as metal seals, friction welding, or heat sealing. While effective, these techniques often pose challenges in terms of speed, reliability, and cost-effectiveness. Moreover, they may not always provide the level of security and stability required to safeguard valuable or delicate cargo during transit.

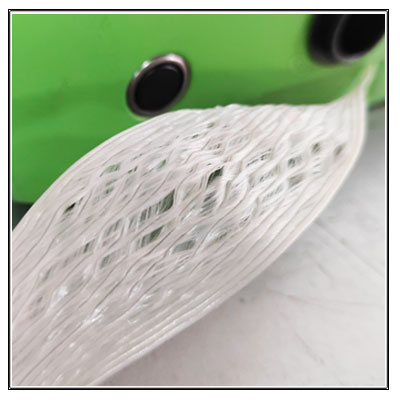

Enter advanced bonded strapping techniques—a cutting-edge approach that leverages the latest advancements in materials science and engineering to overcome these limitations. Unlike traditional strapping methods, which rely on mechanical fasteners or heat fusion, bonded strapping utilizes specially formulated adhesives to create a strong, durable bond between the strapping material and the package. This innovative bonding technology not only ensures superior strength and stability but also enables faster application and greater flexibility in packaging operations.

The recent study, conducted by a team of researchers from leading universities and industry partners, sought to evaluate the efficiency and effectiveness of advanced bonded strapping techniques across various applications and industries. The findings, published in a peer-reviewed journal, revealed a multitude of benefits associated with the adoption of bonded strapping, including:

Increased Speed: One of the most notable findings of the study was the significant improvement in packaging speed achieved with bonded strapping techniques. By eliminating the need for time-consuming mechanical fasteners or heat sealing processes, bonded strapping enabled operators to bundle goods more quickly and efficiently, reducing packaging time and increasing throughput.

Enhanced Stability: Another key advantage of bonded strapping was its ability to provide superior stability and security for packaged goods. The strong bond created by the adhesive ensured that the strapping remained firmly in place during transit, minimizing the risk of shifting, slippage, or damage to the cargo. This enhanced stability not only reduced the likelihood of product loss or breakage but also improved overall supply chain reliability and customer satisfaction.

Cost Savings: In addition to improving operational efficiency, bonded strapping was found to deliver significant cost savings for businesses. By streamlining packaging processes and reducing material waste, companies were able to lower their packaging costs and achieve greater profitability. Moreover, the durability and reliability of bonded strapping helped minimize the need for rework or replacement, further contributing to cost reduction efforts.

Versatility: The study also highlighted the versatility of bonded strapping techniques, which were found to be suitable for a wide range of packaging applications and materials. Whether bundling corrugated boxes, securing pallet loads, or packaging irregularly shaped items, bonded strapping offered a flexible and adaptable solution that could be customized to meet specific packaging requirements.

Environmental Sustainability: Finally, the study emphasized the environmental benefits of bonded strapping, particularly in comparison to traditional strapping methods. By eliminating the need for metal fasteners or heat sealing equipment, bonded strapping reduced energy consumption and material waste, contributing to a more sustainable and eco-friendly packaging process. Additionally, the use of recyclable materials and adhesives further minimized the environmental impact of bonded strapping operations.

Overall, the findings of the study underscored the transformative potential of advanced bonded strapping techniques in improving efficiency, reliability, and sustainability in packaging and logistics operations. As industries continue to prioritize innovation and optimization in the pursuit of competitive advantage, bonded strapping stands out as a proven solution for enhancing productivity, reducing costs, and delivering greater value to customers. With further research and development, the widespread adoption of bonded strapping technologies promises to usher in a new era of efficiency and effectiveness in the packaging industry.

BSTSTRAP

No.30 building, Wuxing High-tech Venture Park

Huzhou City, Zhejiang Province,China

Whatsapp:+86 136 6574 4776

Monday to Saturday 9 am to 5 pm

hailey@bststrap.com

Send us your enquiry anytime

Others News

Bonded Strapping: The Ultimate Solution for Secure and Versatile Packaging

Bonded Strapping: The Ultimate Solution for Secure and Versatile Packaging Innovative Bonded Cord Strapping: A Game-Changer in Packaging Solutions

Innovative Bonded Cord Strapping: A Game-Changer in Packaging Solutions Bonded Cord Strapping: A Durable and Efficient Solution for Industrial Applications

Bonded Cord Strapping: A Durable and Efficient Solution for Industrial Applications Bonded Cord Strapping: A Safe and Cost-Effective Solution for Diverse Industries

Bonded Cord Strapping: A Safe and Cost-Effective Solution for Diverse Industries